| Product Name: | Temperature And Humidity Test Chamber | The Range Of Temperature: | ≤±0.1°C |

|---|---|---|---|

| Voltage: | 220V/50Hz | Heater Power: | 2500w |

| Hatching Rate: | 98% | Weight (KG): | 180 KG |

| Material: | SUS 304SS | Humidity Range: | 20~98%R.H. |

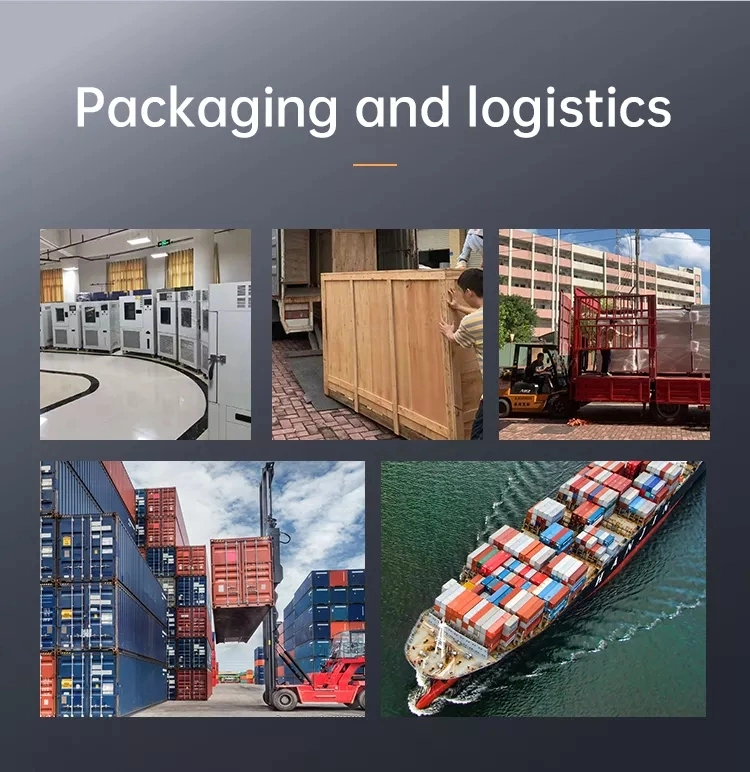

| Volume: | 225L | Packing: | PLY-wood Case |

| High Light: | 304SS Constant Temperature And Humidity Test Equipment,Programmable Damp Climatic Test Chamber,220V 50Hz Climatic Test Chamber |

||

| Model | B-TH-1000B | B-TH-1000C | B-TH-1000E | |

| Capacity | 1000L | |||

| Internal dimensions | 1000mm*1000mm*1000mm(W*H*D) | |||

| External dimensions | 1250mm*2000mm*1910mm(W*H*D) | |||

| Temperature Range | -20ºC ~ + 150ºC | -40ºC ~ + 150ºC | -70ºC ~ + 150ºC | |

| Humidity Range | 20%~98%RH | |||

| Temperature resolution | 0.01ºC | |||

| Humidity resolution | 0.1%R.H | |||

| Temperature deviation | ±0.5ºC | |||

| Humidity deviation | ±2%R.H | |||

| Temperature uniformity | <= 2ºC | |||

| Humidity uniformity | ±3%R.H | |||

| Temperature fluctuation | ±0.5ºC | |||

| Humidity fluctuation | ± 2%R.H | |||

| Heating rate | -70ºC → + 150ºC, >= 3ºC / min | |||

| Cooling rate | 150ºC → -70ºC, >= 1ºC / min | |||

| Humidification system | Stainless steel humidifier | |||

| Heating system | Nickel chromium alloy stainless steel heater | |||

| Water supply system | Front-mounted water supply tank, automatic water supply system | |||

| Controller | Taiwan Visuo Controller | |||

| Case shell | High-quality cold-rolled steel plate electrostatic spray (1.2mm thick) | |||

| Chassis inner wall | SUS304 # stainless steel plate (1.2mm thick) | |||

| Insulation material | 100mm polyurethane rigid foam + 100mm high density glass fiber cotton | |||

| Standard configuration | φ50 test hole, lighting lamp, double-layer vacuum strengthened glass observation window. | |||

| Weight | About 700kg | |||

| Electric current | 40A | 45A | ||

| P ower | 13.5kw | 16kw | ||

| Power supply | Three-phase, 380V | |||

| Safety protection measures | The overall equipment is over temperature, the fan is overheated, the overall equipment is under-phase / reverse-phase, the refrigeration system is overloaded, the refrigeration unit is over-pressured, the overall equipment timing, leakage, operation indication, automatic shutdown after failure alarm, etc. | |||

| Refrigeration Compressors | Imported French Taikang fully enclosed compressor | |||

| Refrigerant | Environmental protection refrigerant R404A / R23 | |||

| Cooling method | Single-stage cooling | Mechanical binary refrigeration | ||

| Blower | Centrifugal fan with forced circulation | |||

| Evaporator | Finned tube heat exchanger | |||

| Condensation method | Air-cooled | |||

| Condenser | Air-cooled scale condenser, cooling fan cooling | Stainless steel brazed plate heat exchanger | ||

| Filter drier | Absorbs residual moisture and acidic substances in the refrigerant of the refrigeration system, and filters out solid rest particles and copper shavings in the system to protect the normal operation of the expansion valve and capillary from ice and dirty plugging | |||

| Control System | |

| Screen display function | 1. Temperature and humidity setting (SV) actual (PV) value is displayed directly 2. Can display the execution program number, segment, remaining time and cycle number, running time display 3. Program editing and graphic curve display 4. With a separate program editing screen, each page can enter 4 segments of temperature and humidity, time 5. Fixed point or program action status display 6. Language conversion can switch Chinese / English 7.7 inch true color display screen |

| Program capacity and control function | 1. Program quantity that can be used: maximum 120 groups, 1 program can be composed of 1 ~ 99 stages, capacity: 1200 stages 2. Commands can be executed repeatedly: each command can be up to 999 times, the temperature and humidity slope can be set by the time axis; 3. The program can be set to connect to use; the production of the program is easy to use conversational operation; with editing, Clear, insert and other functions; group time signal output control (can control the ON / OFF action of the test object) 4. With 9 groups of PID parameter settings 5. With skipping and holding functions during program execution 6. With power-off program memory, it can automatically start and resume the program after power is restored 7. Data acquisition, export, view graphics function 8. PID automatic calculation and FUZZY control function 9. The screen can be adjusted for backlight, and the backlight time can be set 10. On-screen display protection function can be set to close regularly or manually 11. Program copy, COPY, connection function, edit experiment title and other program editing functions 12. With appointment start and shutdown function 13. With date and time adjustment function 14. Button and screen lock (LOCK) function 15. Standby picture viewing function and exception handling picture explanation function |

| Communication interface | 1.R232 / 485 communication 2. Can display curves and obtain data 3. Can be used as a monitoring and remote control system |

| Setting method | Chinese / English interface, touch input |

| Operation mode | Program method / fixed value method |

| Predetermined area | Maximum temperature range: 5 ºC |

| Display resolution | Temperature:0.01ºC;Time:0.1min |

| Power off memory function | Can set power failure recovery mode as: hot start / cold start / stop |

| Input | Platinum resistance |

| Storage function | Standard configuration 2G SD card to record test data curve, can upload and download data, expand storage capacity |

The certificate is valid until June 17, 2024

The certificate is valid until June 17, 2024