Xenon Arc Aging Test Chamber Weathering Resistance Test Equipment Climate Chamber

Products Description

1. Equipment Summary:

Simulation for daily use conditions, inspection helmet long-term sunlight inherit aging ability, and is the impact the pretreatment of the testing steps.

2. Main Function:

Xenon Test Chambers Xenon Lamp Test Chamber has enough space, helmet was put in a uniform irradiation area, and make a helmet doesn't touch enclosure wall, make with high to light bulb distance to 5mm 150mm +, in normal temperature of studio no more than 60 ºC (high-pressure hid xenon lamp) illuminate circumstance, helmet fixed on the stent to test a helmet's aging degree meets the standards.

3. Meet Standard:

Execution standard: GB2812-2006 - T helmet test method

4. Application Industry:

Suitable for safety helmet manufacturer and product development and quality inspection institutions to provide

corresponding environmental simulation and accelerated testing, provide important test basis.

Mainly used in national defense industry, aviation industry, automotive parts, electronic components, plastics industry, food industry and other related product development, straightening management engineering test specifications. Its characteristics are as follows:

1.The import of compressors and refrigeration accessories by the well-known brands in the national boundaries ensures the stability of the refrigeration system.

2.The cause of the faults can be displayed and the reason is easy to exclude.

3.The special air supply cycle design, the temperature and humidity distribution uniformity is good.

4.The whole series of imported microcomputer controllers are colored. Color touch screen, Chinese and English system, can be used as a function of setting the city value. It can show the cause of the trouble, exclude easy, super quiet design, effectively reduce the running noise of the equipment, and

5.Super quiet design, effectively reduce the running noise of the equipment.

6.Multiple safety protection, refrigerant high voltage protection, compressor overload protection, current overload protection, overtemperature protection, leakage protection.

Application range: 1. The core components such as lamp, internal filter, external filter and digital power supply are common with famous European and American brands such as AT and QL, breaking the monopoly of European and American technology.

2. Strictly refer to relevant standards such as GB/T, AATCC, ASTM, GME, GMW, ISO, JASO, SAE, VDA, VW, etc.

3. The main functional components are all equipped with the world famous brand configuration, real reproduction of the outdoor climate light, heat, humidity and rainfall, etc., the artificial accelerated aging test of the sample

Features: 1. Full spectrum xenon lamp.

2. A variety of alternative filtration systems.

3. Water spray function.

4. Relative humidity control.

5. Test chamber air temperature control system.

6. Irregular shape flat product rack for easy product placement

7. The original imported Xenon arc lamp.

8. The installation is easy to use and basically does not require daily maintenance features.

9. The service life of the xenon arc tube depends on the level of irradiance used. The life of the lamp is generally 1600 hours. Lamp replacement is quick and easy, and long-lasting filters provide the protection needed to maintain the spectrum.

Temperature humidity Test chamber can be used as the basis of improving product or reference.It is ideally suitable for electronic, LED lighting industry, auto parts, chemical industry, building materials, mobile computers, batteries, plastic, metal, rubber etc.material.xenon test chamber

Structural characteristics: Imported intelligent temperature and humidity controller for temperature control, with PID adjustment, fast self-tuning, can set a variety of parameters, temperature direct digital display, reading is very convenien

| Specification |

Studio size :

W × D × H |

W500×D600×H500 mm |

Humidity range: |

20 to 98% R.H |

Appearance size:

W×D×H |

About 1100×1300×2000mm |

Humidity deviation: |

±2.5%R.H (humidity ≥75%R.H) ±3%R.H (humidity ≤75%R.H) (without light) |

| temperature range: |

0°C~80°C |

Type of light source: |

Imported air-cooled full solar spectrum long arc xenon lamp

(average service life of about 1600 hours) |

| Temperature deviation: |

±2°C

(without lighting) |

Rainfall time: |

1 to 9999 minutes, adjustable |

| Rainfall period: |

1 to 9999 minutes, adjustable interval (off) |

Spectral wavelength: |

290nm~800nm |

| Xenon lamp power: |

1 branch, 6000W

(life: 1600 hours) |

heating power: |

About 4KW |

| Humidification power: |

About 2KW |

Lighting time: |

Continuous programming |

| Source irradiance: |

0.4-1.22 W/M2 (at 420nm) adjustable |

|

| 200-1200W/M2 (at 200-800nm) adjustable |

| 0.2-0.57 W/M2 (at 340nm) adjustable |

| Blackboard temperature: |

0°C~110°C±3°C |

| Cooling method: |

Mechanical refrigeration air cooling |

5. Main specifications:

| Product Name |

Xenon Test Chambers Xenon Lamp Test Chamber |

| Xenon lamp parameters |

450W high-voltage |

| Xenon lamp distance with distance |

150mm |

| At the same time, you can try |

Up to two helmet |

| Volum |

100×50×50cm |

| Weight |

42kg |

| Power Supply |

AC220V,3A |

FAQ

If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation muanual. We can provide operation video for machines.

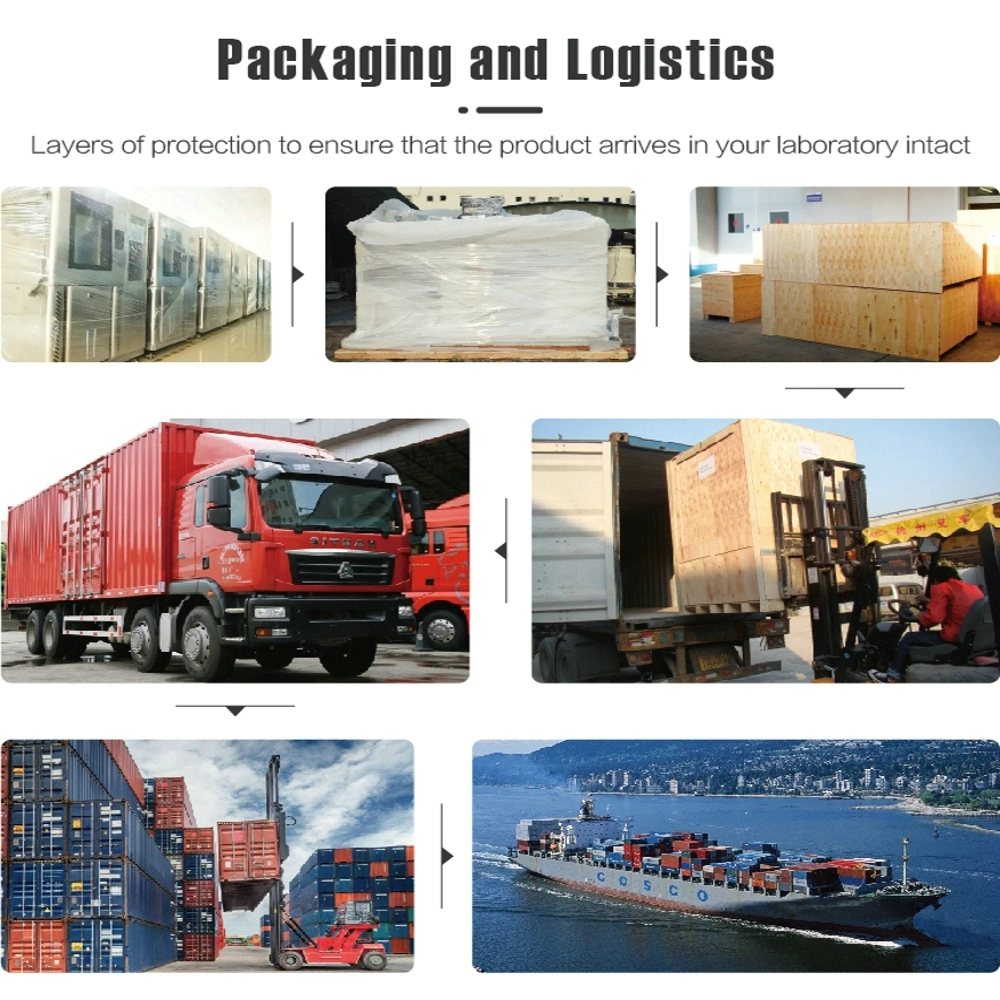

Onsite Service:

1. Device installation;

2. Equipment Operation Test Technology training;

3. Equipment Calibration;

4. Daily maintenance and maintenance of equipment

Free technical training for visiting factories

24-hour Online contact

Free software upgrades

Free information:

1.Product Instruction;2.Product operation instruction/video;3.Experiment Test (test application, test report)

Device Problem Handling:

1. Social media 24 hours online communication;

2. Mail Seamless Docking;

3. Video Conferencing;

4. Artificial free door-to-door service

Work shop:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!