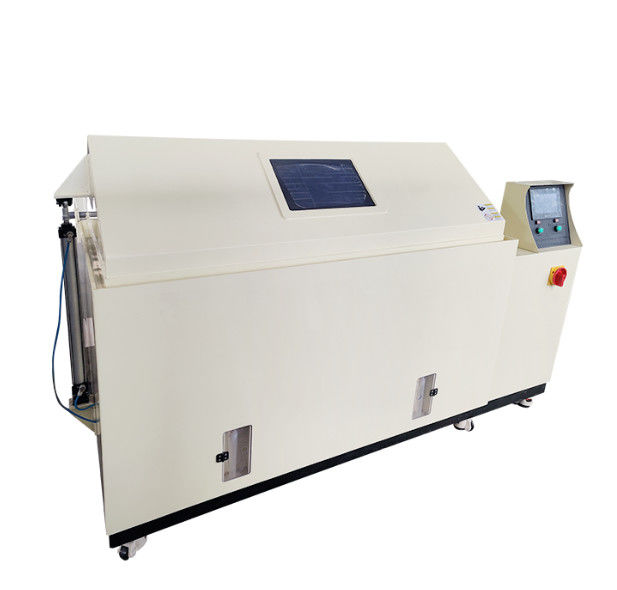

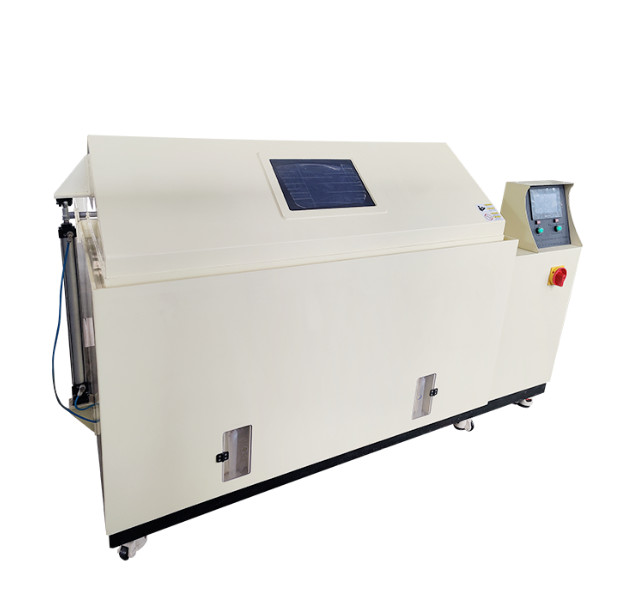

Salt Spray corrosion Test Machine Price Used Salt Spray Chamber Salt Spray Test Chamber

1. The system has leakage protection function;

2. The studio has dual functions of electronic over-temperature protection and mechanical over-temperature protection;

3. Electronic over-temperature protection in saturated barrel;

4. The saturator will automatically alarm for dry burning and automatically turn off the system power;

5. Decompression and control device with dual injection pressure of air inlet and outlet;

6. There is an anti-aging overflow hole at the bottom of the laboratory;

7. Over current protection;

8,The non-contact SSR solid state relay temperature control method has the characteristics of no arc and noise;

9. Grounding protection.

Random Accessories

1: V-shaped/O-shaped shelf 1 set

2: Reagent sodium chloride 2 bottles (500g/bottle)

3: Operation manual 1 copy

4: 1 plastic anti-rust bucket (5L capacity)

1. Machine material:

(A) testing room using PVC polyvinyl chloride plate (from Taiwan), acid-resisting and alkali-resisting, cleaning easier.

(B) cover of testing room using acrylic panels (imported organic glass), the thickness is 5mm.

(C) reagents added bottles attached with water gauge, cleaning easy and not easy to break.

(D) saturated air barrels is made of SUS # 304 stainless steel.

(E) testing room to adopt indexing frame, can be arbitrarily adjust the angle, Surrounded by fog and placed more piece .

2. According to CNS JIS ASTM GB2423.19 specifications, can be set constant temperature to control

(A) Salt spray test: NSS, ACSS

1. testing room : 35 ℃ ± 1 ℃

2 saturated air barrels : 47 ℃ ± 1 ℃

(B) anti-corrosion test: CASS (copper acetate)

1.testing room: 50 ℃ ± 1 ℃

2 saturated air barrels: 63 ℃ ± 1 ℃

3. Aair supply system: air pressure 1Kg/cm2 Two-stage adjustments (coarse / fine-tuning).

(A) the first paragraph for the rough adjustment 2-2.5Kg/cm2, the second paragraph to fine-tune 1Kg/cm2.

(B) Testing configuration is switch connector designed for SO2.

4. Spray form:

(A) Using Bo Nute principle to draw brine and then saline spray, atomization uniform, non-blocking and crystallization, so that ensure continuous spraying.

(B) Nozzle: The nozzle is made of special glass, adjust spray volume and spray angle.

(C) spray volume: Adjustable 1 ~ 2ml (80cm2/hr) (average of 16-hour volume).

5. Heating devices:

By direct heating, warming up faster and reduction of standby time, when the temperature arrives automatically switch ON / OFF, make temperature accuracy, low power consumption (heating tube is made of titanium alloy).

6.The control system:

(A) testing room temperature controller is the digital micro-computer products 0-99.9 ℃, liquid crystal digital display with PID automatic calculation, the control error is ± 0.3 ℃ (YANG MING6802) 1 pcs.

(B) saturated air barrels controller 0 ~ 99.9 ℃, liquid crystal digital display with PID automatic calculation, the control error is ± 0.3 ℃ (YANG MING6802) 1 pcs.

(C) safe temperature controller of heat expansion of the liquid tank 30 ~ 110 ℃ (Italy) 1 pcs.

(D) safe temperature controller of expansion of the saturated air barrel : 30 ~ 110 ℃ (Italy) 1 pcs.

(E) digital time controller 9.9s ~ 9990hr (Taiwan) 1 pcs.

(F) timer 0 ~ 9999hr (Taiwan Anliang) 1 pcs.

(G) buckle switch, continuous buckling 20000 times.

(H) 60 type, 90 type for manual flip, 120, 160, 200 type for the pneumatic cylinde automatic opening and closing.

(J) pressure gauge, (Taiwan B card).

(K) fixture bleaker (YANG MING).

(L) electromagnetic valve; (KSD).

(M) regulating valve (YIHUA).

(N) bleaker (Omron).

7.Add water systems:

Using automatic water replenishment system, automatic replenishment when the water level is too low.

8.Safe protective device:

(A) low water level, automatically cut off power supply.

(B) over-temperature, automatic cut off the power supply.

(C) attached to the safe warning light device.

| Model |

BT-609-60 |

BT-609-90 |

BT-609-120 |

BT-609-150 |

BT-609-200 |

| Design standard |

GB/T 10587-2006, GB/T 10125-1997,

JIS-D0201, H8502, H8610, K5400, Z2371

|

| Test chamber capacity(L) |

108L |

270L |

600L |

750L |

1000L |

|

Temperature

|

Test chamber |

NSS.ACSS 35°C±1°C/CASS 50°C±1°C |

| Saturated air cylinder |

NSS.ACSS 47°C±1°C/CASS 63°C±1°C |

|

Test chamber size

L×W×D(cm)

|

60*45*40 |

90*60*50 |

1200*1000*500 |

1500*1000*500 |

2000*1000*500 |

| Max capacity of test liquid(L) |

15 |

25 |

40 |

40 |

40 |

| Power |

AC220V,10A |

AC220V,15A |

AC220V, 30A |

AC220V, 30A |

AC220V, 30A

|

COMPANY INFORMATION

BOTO GROUP Ltd. is a private enterprise integrating R&D, production, OEM and sales of scientific and technological equipment manufacturing. Proficient in the production, development and upgrading of various non-standard instruments and automatic instruments. The factory covers an area of 26,666 square meters, headquartered in Shanghai, has several offices in China, the factory annual output of about 2000 sets of equipment. Since the establishment of the company, the company is committed to providing customers with quality products and services, and has been praised by customers.

Main equipment

- Constant Temperature and Humidity Test Chamber

- Salt Spray Test Chamber / Corrosion Cyclic Salt Spray Test Chamber

- UV Accelerated Aging Test Chamber

- Mini Environmental chamber / Desktop Environmental Test Chamber

- Walk in Constant Temperature and Humidity Lab

- High Temperature Chamber and Other Lab Test Equipment etc.

In the domestic market, we have many end customers, third-party testing institutions, research institutes, leading enterprises in different industries, and some agents. For the overseas market, we hope to find more general agents, distributors and importers to cooperate together.

Main market

The factory has the ability to calibrate, and the customer can also designate a third party organization to calibrate and issue a calibration report.

Production Details

Factory Inspection

We control quality from the materials, electronic parts, controller,comppressor, solenoid valve, and many parts of the products.

Workshop Machine

Certification

Cooperative partners

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!