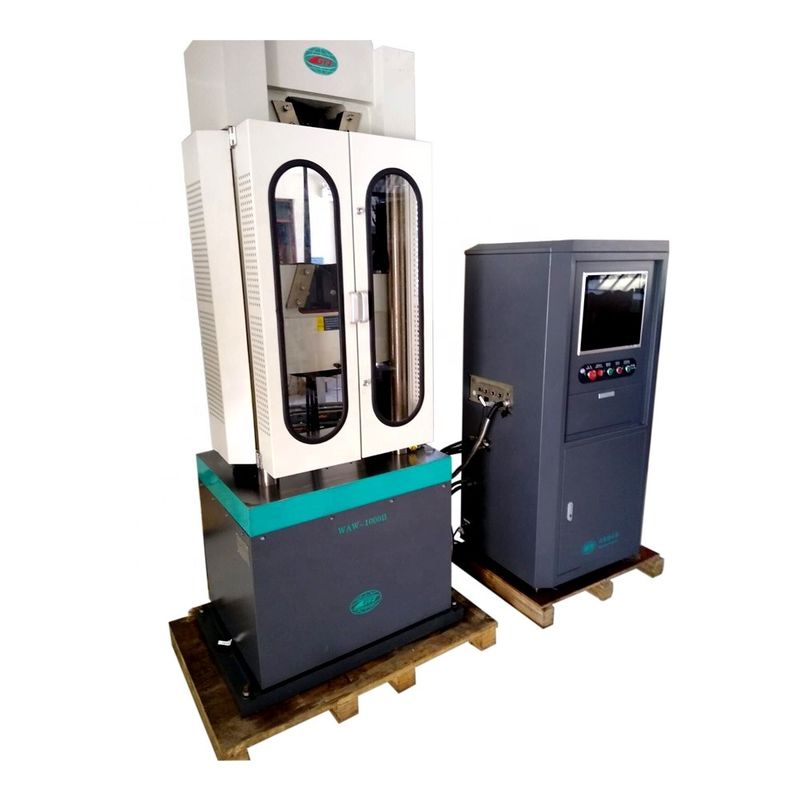

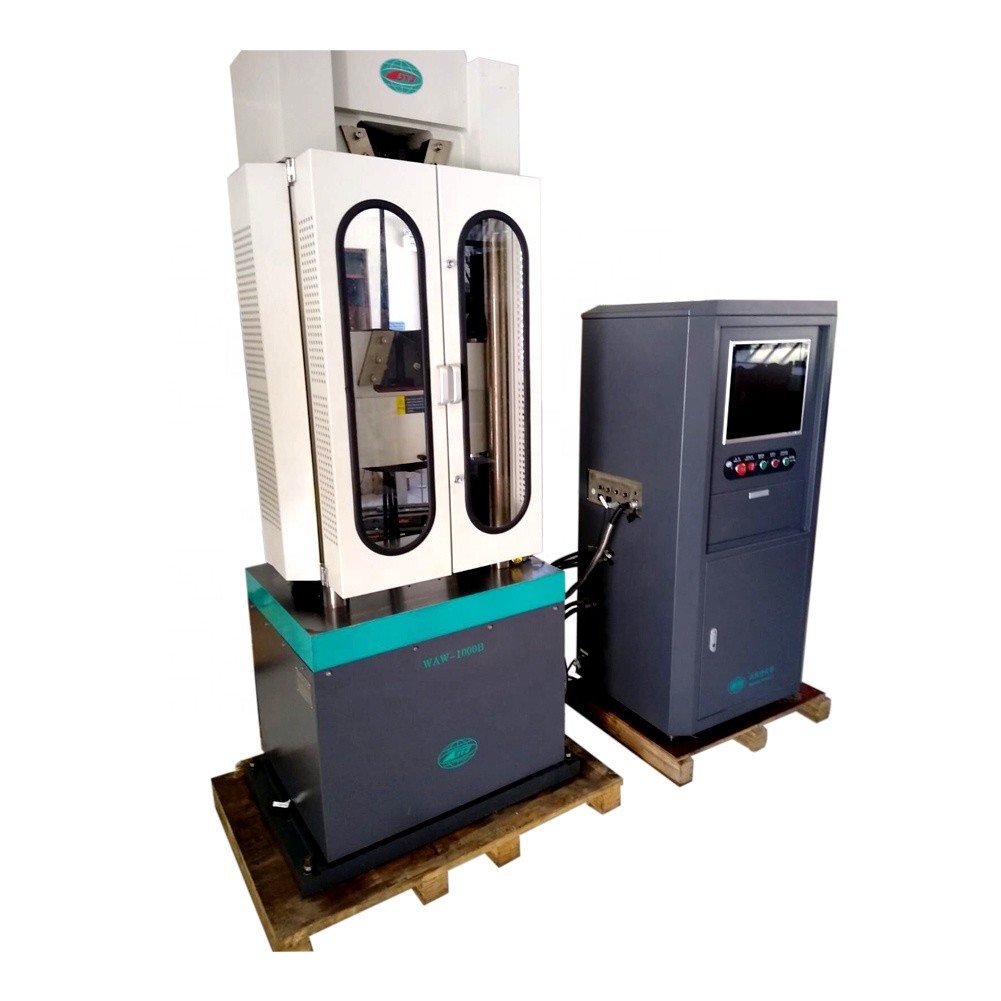

Universal automatic tensile testing machines

This series of testing machines is clamped in the form of hydraulic jaws,controlled by a hand-controlled valve to control the testing machine,and a testing machine that displays the test curve by a microcomputer screen display.lt is mainly used to stretch,compress and bend metal and non-metal materials.Tests such as cutting,shearing,etc.,computter screen display load curve,force value,loading speed,displacement,etc.,aytomatically record data,print data results.The host uses four-column double-screw test space architevture and high-strength,high-toughness,and beautiful protection nets for securityprotection.It is a necessary equipment for research institutes,matallurgy and machinery factories,quality in spection stations,and universities and colleges.

The series electronic type testing machine is widely used for the mechanical testing of stretching, compressing, bending, shearing, peeling and tearing of non-metal materials, such as rubber, plastics, fabrics, electric wires and cables, composite materials, leather, waterproof roll, non-woven fabrics, earthwork cloth and paper sheets, etc. as well as the metal materials, such as metal wire, metal foil, metal sheets and metal bars, etc. The universal testing machine is suitable to be used in the fields, such as quality inspection, education and scientific research, aerospace, ferrous metallurgy, automobile industry and construction and building materials, etc.

Hydraulic servo-controlled system regulating the load rate

Four thick columns and two lead screws grant high structural stiffness

Two different work spaces, the upper one for tension and the lower one for compression, bending and shearing, for a comfortable test execution

High precision load cell, class 1 according to ISO 376 standard, ensures accurate force measurement

Hydraulic jaws, for stronger clamping of the specimens

Integrated displacement photoelectric encoder

Movable lower crosshead with button panel for an easy machine operation and specimens positioning

Compression platens included for an easy mach

Parameters:

| WAW-B Technical Parameters |

| Model |

WAW-300B |

WAW-600B |

WAW-1000B |

| Maximum test force(kN) |

300 |

600 |

1000 |

| Accuracy level |

1 |

| Collection method |

Spoke load sensor |

| Piston stroke(mm) |

200 |

| Clamping method |

Hydraulic |

| Test control method |

Microcomputer servo control |

| Compression test space(mm) |

600 |

| Tensile test space(mm) |

700 |

| Total power(kW) |

1.5 |

| Compression platen(mm) |

Φ148 |

Φ198 |

Φ225 |

| Round sample clamping range(mm) |

Φ10-30 |

Φ13-40 |

Φ13-40 |

| Flat sample clamping range(mm) |

0-10 |

0-15 |

0-20 |

| Bending fulcrum span(mm) |

50-300 |

| Bending heart / stick diameter(mm) |

50/50 |

| Number of columns (screws) |

6 column |

| Mainframe dimensions(mm) |

810*560*1910 |

880*570*2050 |

940*640*2250 |

| Host weight(kg) |

≈1620 |

≈2000 |

≈2600 |

| Control cabinet size(mm) |

1010*640*840 |

| Control cabinet weight(kg) |

150 |

BOTO Testing equipment Technology Co., Ltd is a high technology supported production-oriented enterprise who specializes in developing, manufacturing, marketing all kinds of environmental equipment. Our company has advanced technology, experienced technical management personnel and efficient professional service staffs, fine quality management and perfect after-sales service system.

Our company mainly produce simulated environmental tester, plastic and rubber tester etc. on all kinds of materials testing industries. The production base is located in the country’s manufacturing center Dongguan, Guangdong province, China. In order to service our customers better in terms of reducing costs and early delivery, in 2005 we had set up an office in Kunshan, Jiangsu province for Eastern China marketing and servicing.

BOTO deals with customers from more than 150 countries and regions. Meanwhile, we are committed to cooperate with different dealers in different countries and regions in order to offer better service. Our mission is to help every customers establish testing labs to ensure the quality of their products.

Our company will continue to develop, innovate and keep faith. We combine with the international testing standards and the specific demands of customers that may establish a new banner in Chinese testing industry.

Production Process

Factory Inspection

We control quality from the materials, electronic parts, controller,comppressor, solenoid valve, and many parts of the products.

Main market

The factory has the ability to calibrate, and the customer can also designate a ISO 17025 accredited third-party organization to calibrate and issue a calibration report.

Certification

The certificate is valid until June 17, 2024

Cooperative partners

BOTO ADVANTAGE

Our Services

During the whole business process, we offer Consultative Selling service.

1) Customer inquiry process:

Discussing testing requirements and technical details, suggested suitable products to customer to confirm. Then quote most suitable price according to customer requirements.

2) Specifications customize process:

Drawing related drawings to confirm with customer for customized requirements. Offer reference photos to show the products appearance. Then, confirm the final solution and confirm final price with customer.

3) Production and delivery process:

We will produce the machines according to confirmed PO requirements. Offering photos to show production process.

After finish production, offer photos to customer to confirm again with the machine. Then do own factory calibration or third party calibration(as customer requirements). Check and test all the details and then arrange packing.

Deliver the products in confirmed shipping time and inform customer.

4) Installation and after sale service:

Defines installing those products in the field and providing after-sales support.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!