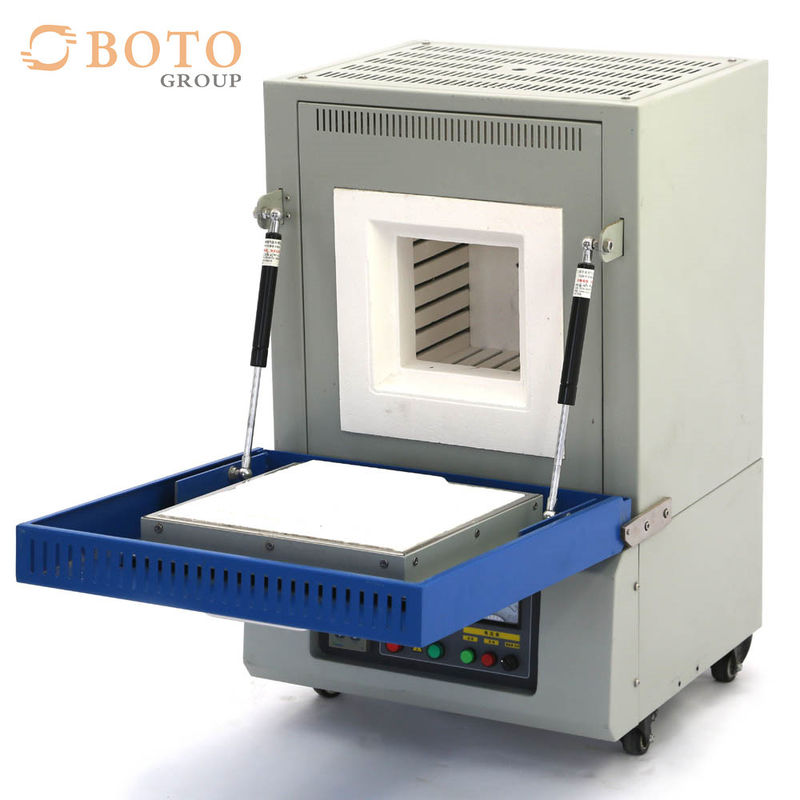

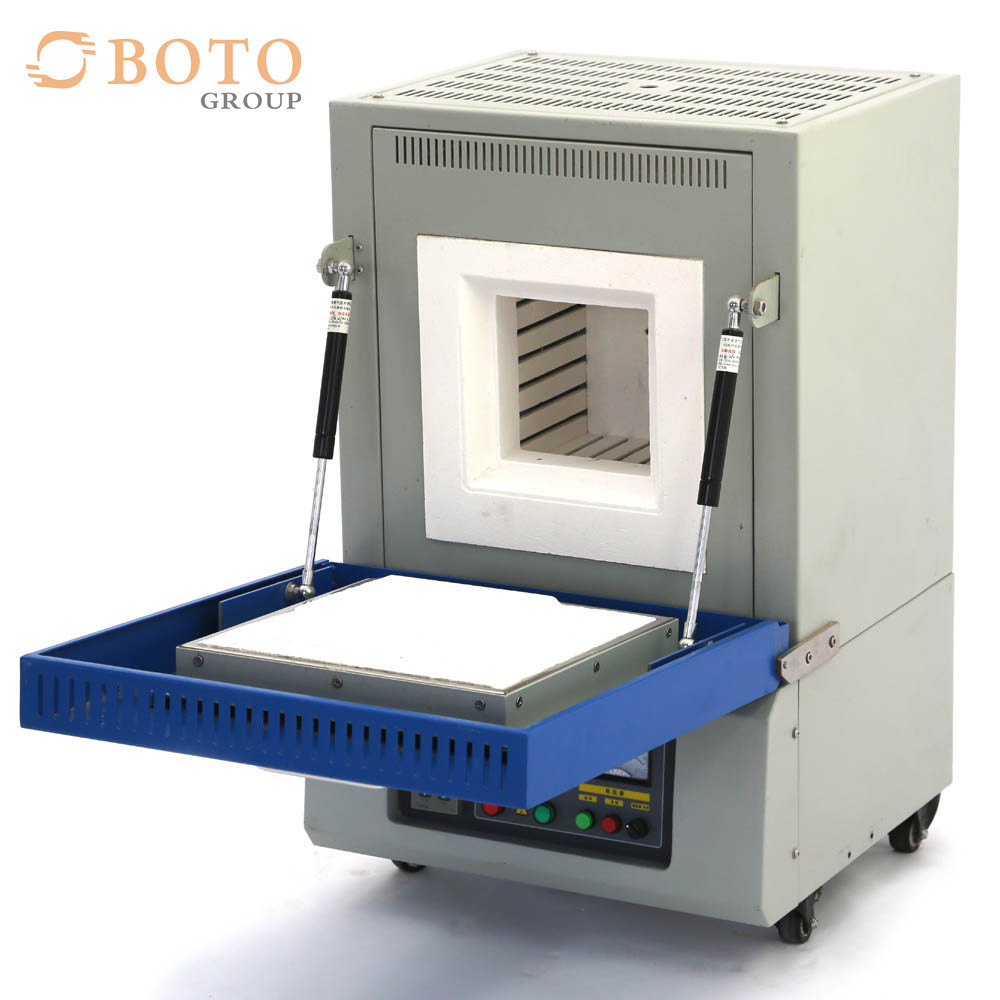

Laboratory Material Testing High Temperature Electric Muffle Vacuum Furnace

This Series atmosphere muffle furnace is adopted imported heat-preservation material, high purity alumina polycrystalline fiber. Temperature is controlled by double platinum rhodium thermal couple and Al intelligent temperature controller 708P.

The atmosphere furnaces can protect materials from oxidation and decarburization with flowing Nitrogen, Argon and other inert gas, balanced temperature field, fast temperature rising and cooling, energy-efficient, delicate appearance,practical.It is widely used for sintering, annealing, reducing with inert atmosphere in labs of colleges and universities, research institutes and industrial and mining enterprise.

Features

• Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

• Built-in ammeter and dual voltmeters for easy monitoring and troubleshooting.

• Built-in computer interface.

• Long life type K thermocouple.

• CE compliant

Safety

• Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller's manual) or when the thermocouple is broken or malfunctions.

• Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

Characteristic

11) high temperature BOX series muffle furnace, the control system is an international leading, with safe and reliable, simple operation, convenient maintenance.

2) Use 708P type temperature controller (Professional PID programmable control) for automatic temperature control with high temperature control precision (±1ºC). the temperature range is wide, and high uniformity of furnace temperature.

3) Furnace chamber adopts the vacuum suction molding alumina fiber, has the characteristics of energy saving, light volume, high cooling speed, the temperature field balancing, good thermal shock resistance ability.

4) Furnace body have the internal and external double-layer structure, heat insulation effect is good, the outer furnace wall temperature is low. Fast heating and heat preservation performance is good, the energy saving effect is obvious.

5) Equipped with rapid air cooling system. Oven door and oven door frame to cool the air cooling design, guarantee the oven door use for a long time not out of shape.

6) The stove top can install vent, furnace and control system integration design, compact and beautiful.

Technical Parameter:

| Model |

BTLY-1700C |

BTLY-1700C |

| Power supply |

AC220V 50/60HZ |

AC220V 50/60HZ |

AC380V 50/60HZ |

|

Furnace chamber

(D x W x H)

|

160*150*150mm |

300*250*200mm |

400*300*300mm (Customizable) |

| Overall size |

620*620*900mm |

620*680*1050mm |

640*760*1600mm |

| Rated power |

4KW |

6KW |

14KW |

| Weight |

130kg |

150kg |

400kg |

| Furnace chamber |

1700 type imported alumina polycrystalline fibers furnace chamber, scientific design and with durable, good insulation properties. |

| Heating elements |

High quality silicon molybdenum rod |

| Thermocouple |

B-type double platinum rhodium thermocouple |

| Temperature control mode |

The temperature control system uses artificial intelligence technology, with PID control, self - tuning function, 50 segment heating and cooling program. |

| Continuous working temperature |

≤1600℃ |

| Maximum temperature |

1650℃ |

| Recommended heating rate |

10℃/min |

| Temperature control accuracy |

±1℃ |

| Standard accessories |

Door brick 1 piece

Crucible tongs 1 piece

|

| Optional accessories |

Furnace hobs, a variety of corundum crucible, oven glove, computer control software and paperless recorder, etc. |

BOTO Testing equipment Technology Co., Ltd is a high technology supported production-oriented enterprise who specializes in developing, manufacturing, marketing all kinds of environmental equipment. Our company has advanced technology, experienced technical management personnel and efficient professional service staffs, fine quality management and perfect after-sales service system.

Our company mainly produce simulated environmental tester, plastic and rubber tester etc. on all kinds of materials testing industries. The production base is located in the country’s manufacturing center Dongguan, Guangdong province, China. In order to service our customers better in terms of reducing costs and early delivery, in 2005 we had set up an office in Kunshan, Jiangsu province for Eastern China marketing and servicing.

BOTO deals with customers from more than 150 countries and regions. Meanwhile, we are committed to cooperate with different dealers in different countries and regions in order to offer better service. Our mission is to help every customers establish testing labs to ensure the quality of their products.

Our company will continue to develop, innovate and keep faith. We combine with the international testing standards and the specific demands of customers that may establish a new banner in Chinese testing industry.

Work shop:

Contact way:

Jerry Yin

Email: sales6@botomachine.com

Whatsapp/phone: +861322137662

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!