Standard Parameters:

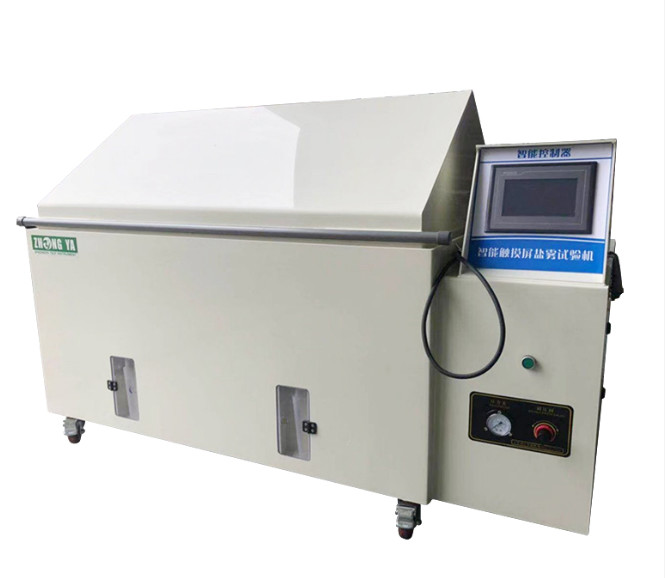

1. Model: BT-ZY-YWX-60 BT-ZY-YWX-90 BT-ZY-YWX-120

2.I nner box size(mm): 600*450*400 900*600*500 1200*800*500(W*D*H)

3. outside size(mm): 1100*600*950 1400*750*1050 1700*950*1050(W*D*H)

4, Satisfy the test method: Integrate the three tests of NSS, AASS and CASS, which can carry out neutral salt spray test (NSS test), acetic acid salt spray test (ASS test) and copper accelerated acetic acid test (CASS), etc.;

5, Test chamber temperature range:RT+10℃~60℃;

6, Saturation barrel temperature range:RT+10℃~70℃;

7, Temperature fluctuation:≤±0.5℃;

8, Temperature uniformity:≤±2℃;

9, Temperature deviation:≤±2℃;

10, Salt fog precipitation:1~2ml/80cm2*h(16Haverage value);

11, Spray method: pneumatic, continuous, intermittent, programmable and other spray methods;

12, Spray pressure: 0~0.25Mpa adjustable;

Safety protection function:

1. The system has leakage protection function;

2. The studio has dual functions of electronic over-temperature protection and mechanical over-temperature protection;

3. Electronic over-temperature protection in saturated barrel;

4. The saturator will automatically alarm for dry burning and automatically turn off the system power;

5. Decompression and control device with dual injection pressure of air inlet and outlet;

6. There is an anti-aging overflow hole at the bottom of the laboratory;

7. Over current protection;

8,The non-contact SSR solid state relay temperature control method has the characteristics of no arc and noise;

9. Grounding protection.

Random Accessories

1: V-shaped/O-shaped shelf 1 set

2: Reagent sodium chloride 2 bottles (500g/bottle)

3: Operation manual 1 copy

4: 1 plastic anti-rust bucket (5L capacity)

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!