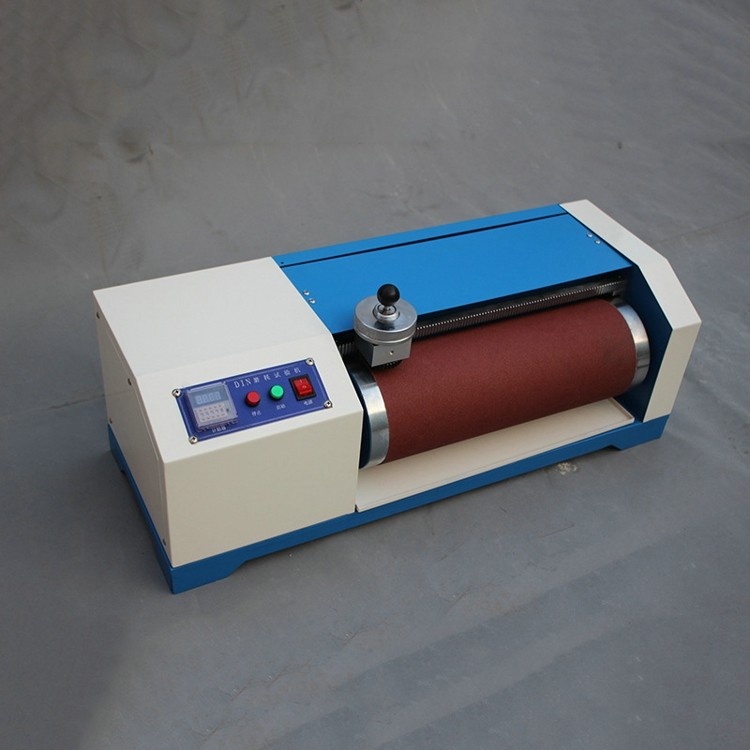

Universal CE DIN Rubber Abrasion Friction Tester DIN Abrasion Testing Machine

Summary:

Din Abrasion Tester is suitable to determine the

wear resistance of elastic material, rubber, tires,

conveyor belts, shoe soles, soft synthetic leather

and other materials.

Equipment summary:

The main function of CE DIN Rubber Abrasion Resistance Testing Machine is to test the friction of surface by a particular piece of sandpaper.After friction for a certain time, and then assess the condition of material surface, weight, volume and thickness, from this standard to assess the abrasive nature of materials.

Main functions:

This CE DIN Rubber Abrasion Resistance Testing Machine is a high efficiency, good reproducibility and easy to operate, applied to test the abrasive nature of material, as such elastic material, rubber, tires, convey belt, transmit belt, sole, synthetic leather, leather and others.

Corresponding standard:

This rubber abrasive test device meet DIN-53516ISO-4649GB/T9867-88

Applicable industry:

This CE DIN Rubber Abrasion Resistance Testing Machine applied to test leather performance in shoes, clothing, luggage handbag industry, research laboratories; commodity inspection, arbitration and technical supervision departments.

Principles:

Under a predetermined contact pressure and a given area ,the specimen with sandpaper angled to measure

abrasion resistance of the specimen subjected to rubbing on a certain level of sandpaper, sandpaper affixed

to the surface of the drum, samples pressed on a drum with sandpaper, and the specimen along the roller to

the lateral movement, abrasion resistance is produced at one end of the cylindrical specimen, tests the

value of the mass loss of the specimen, by the density of the specimen to calculate the amount of volume

abrasion.

Specifications :

| Roll diameter |

150mm |

| Fixture lateral displacement |

4.2mm/hoop each lap |

| Rolling speed |

40rpm |

| Load |

2.5N, 5N, 7.5N, 10N |

| Specimen size |

thickness 6mm~14mm |

| Dimension |

850*380*400mm |

| Weight |

Approx 70kg |

| Power |

220V 50HZ |

| Sample load |

2.5N ±0.2N / 5 N ±0.2N |

| Roller wheel diameter |

(150 ±0.2)mm |

| Roller wheel length |

460mm |

| Roller wheel revolving speed |

40±1r.p.m |

| Abrasion stroke |

40m equal to roller wheel turns number 84 |

| Abrasion speed |

0.32m/sec |

| Dip angle |

3°(included angle between sample clamp holder and vertical plane of roller wheel) |

| Volume (approx.) |

70cm ×30cm ×30cm |

| Weight (approx.) |

50kg |

| Power |

AC 220V 3A(specified) |

Q1: What is your warranty ?

A: 12 months product warranty, but lifetime for services. Free Non-consumable components will be provided if any performance failure occurs within 12 months caused by non-human damage.

Q2: How-to vedio provided ?

A: Yes. if required, our engineers will record a specialize how-to video for you.

Q3: Are your company a trading one or a factory?

A: Yes, we are a manufactured factory & trade (integration).15 years focusing on test instruments field. 6 years exporting experience, warmly welcome to visit our plant (factory), we also support OEM and ODM.

Q4: After an order is placed, when to deliver?

A: Generally about 25 days. If we have inventory, we can arrange shipment within 7 days. Please be aware that our production lead times depend on specific items and item quantities.

Q5: What about the after-sales service and product’s quality?

A: 12 months warranty. After the warranty, the professional after-sale service team will provide perfect technical support.and help customer solve problems encountered while using our product, handies guest problems and complaints professionally and timely. Each instruments must be carried out 100% quality examination and test when shipping and delivery goods. Product use training, each of our product provide video training to show you how to install & operate. Engineers would be go abroad to training, repair and others help you need.

Q6: what about the packing of equipment?

A: Covered with air bubble film before put the machine into the stanard exporting wooden case, which not only has good shock absorption, impact resistance, heat sso has the advantag- es of nontoxic, odorless, moisture corrosion, good transparency etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!