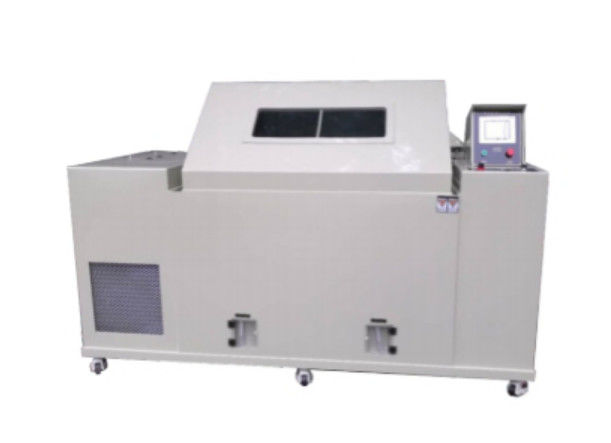

Corrosion Testing Equipment Temperature and humidity combined salt spray corrosion test chamber Salt Spray Test Chamber

Product description

After surface electroplating, anodizing, spraying and anti-rust oil anti-corrosion treatment, test the corrosion resistance of various materials. The salt spray corrosion test chamber can be used to examine the ability of the material and its protective layer to resist salt spray corrosion, and the process quality comparison of similar protective layer can also be used to examine the ability of some products to resist salt spray corrosion. The equipment can reach any temperature point from normal temperature to 50℃ in the test workspace, and keep constant.

Standard

Comply with MIL STD GB JIS JEDEC IEC ISI and other test specifications

Use

After surface electroplating, anodizing, spraying and anti-rust oil anti-corrosion treatment, test the corrosion resistance of various materials. The salt spray corrosion test chamber can be used to examine the ability of the material and its protective layer to resist salt spray corrosion, and the process quality comparison of similar protective layer can also be used to examine the ability of some products to resist salt spray corrosion. The equipment can reach any temperature point from normal temperature to 50℃ in the test workspace, and keep constant.

Features

1. Adopts high-precision imported touch screen temperature special intelligent controller to achieve effective control of temperature, humidity and dryness;

2. Polar air intake depressurization. Ensure the spray pressure is stable;

3. Conical disperser at the top of spray tower, with salt spray guidance and adjustment of salt spray uniformity and settling amount;

4. Perfect protection function (water shortage, super wet, overload, etc.) and equipped with sound, alarm, stop function;

5. Saturate the compressed air used for spraying to ensure the stable test environment conditions and effectively prevent nozzle blocking;

6. Equipped with the device running time controller, it will automatically shut down after the running time is exhausted.

Spec:(Non-standard custom walk-in compound salt spray laboratory)

| Model |

B-CCT-60 |

B-CCT-90 |

B-CCT-120 |

B-CCT-160 |

B-CCT-200 |

| Internal Dim(cm) |

60x45x40 |

90x60x50 |

120x100x50 |

160x100x50 |

200x100x50 |

| External Dim(cm) |

108x63x119 |

140x80x139 |

178x120x149 |

230x130x149 |

270x130x159 |

| Cabinet Material |

Corrosion-resistant polymer material |

| Relative Humidity |

20%~98%RH(10%~98%RH Non-standard optional) |

| Laboratory Temperature(℃) |

A:25℃~70℃ B:0℃~70℃ C:-20℃~70℃ D:-40℃~70℃ |

| Temp Uniformity |

±1℃ |

| Temp&Humi.Deviation |

±1.0℃/±3.0%RH |

| Temp Fluctudtion |

±2.0℃/±3.0%RH(>75%RH) |

| Saturated air barrel temp(℃) |

Saline test method:35±1℃/Corrosion test method:50±1℃ |

| Saturated air pressure(kg/cm2) |

Saline test method:47±1℃/Corrosion test method:63±1℃ |

| Saturated air pressure(kg/cm2) |

0.8~2.0±0.01 |

| Salt spray sedimentation rate(ml/80cm2.h) |

1~2ml/80cm2.h(Controllable) |

| PH value |

Saline test method:6.5~7.2/Corrosion test method:3.0~3.2 |

| Spray Mode |

Continuous spray/gap spray(adjustable may be provided) |

| Power Source |

AC:220V 50Hz /AC:380V 60Hz |

Detail drawing

Structure system: box, sprayer, nozzle, dehumidifier

Safety system: fault buzzing, three-color light, overtemperature protection, overload protection, differential oil pressure protection, phase sequence protection

Other accessories: power cord, sample holder, fog collecting measuring cup

FAQ

Q1: How can i get a quotation?

A1: Kindly provide us your details request (inner chamber size, temperature range, humidity range, power supply, product, etc.), leave us an inquiry or email and we will response promptly!

Q2: What's your temperature & humidity range?

A1: Our standards temperature range is -70℃~+180℃, 20%~98%RH.

We also can do Ultra low temperature to -190℃ .

Q3: What's your rate of heating & cooling?

A3: Our standards rate is average 3℃/min for heating, 2℃/min for cooling.

3℃/min,5℃/min,8℃/min,10℃/min,15℃/min linear or non-linear speed is available for us.

Q4: What's your warranty?

A4: 12 Months (Noted: free spares parts can be offered during warranty period, exclude consumables and man-made damages), life-time technical service

Factory introduction

BOTO GROUP LTD.Is a professional manufacturer of environmental test equipment and test service. Our company was established in 1998,the plant covers 55,000 square meters and a construction area of 6,800 square meters, existing 160 workers and we can provide operation video for machines.

Service

If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation muanual. We can provide operation video for machines.

Onsite Service: 1.Device installation; 2.Equipment Operation Technology training; 3.Equipment Calibration; 4.Daily maintenance maintenance of equipment.

Free technical training for visiting factories

24-hour Online contact

Free software upgrades

Free information:

1.Product Instruction;

2.Product operation instruction/video;

3.Experiment Test (test application, test report)

Device Problem Handling:

1.Social media 24 hours online communication;

2.Mail Seamless Docking;

3.Video Conferencing;

4.Artificial free door-to-door service

Our Team

BOTO ADVANTAGE

Customers photos

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!