Salt Spray Prohesion Test Chamber

Cyclic corrosion testing provides the best possible laboratory simulation of natural atmospheric corrosion.

Research indicates that test results are similar to outdoors in resulting structure, morphology, and relative corrosion rates.

Cyclic corrosion chambers from BOTO GROUP can run traditional salt spray, Prohesion, and most cyclic automotive tests.

Chambers are available in different sizes to fulfill a wide range of testing requirements.

Cyclic corrosion testers are the simplest, most reliable, and easiest to use corrosion testers available.

Overview Cyclic Corrosion Testing

Prior to cyclic corrosion testing, conventional salt spray (a continuous salt spray at 35˚C), was the standard way to simulate corrosion in a lab. Because conventional salt spray methods failed to mimic the natural wet/dry cycles of the outdoors, test results frequently provided poor correlation to outdoors.

In a cyclic corrosion tester, specimens are exposed to a series of different environments in a repetitive cycle that mimics the outdoors. Simple cycles, such as Prohesion, may consist of cycling between salt fog and dry conditions.

More sophisticated automotive methods may call for multi-step cycles that incorporate humidity or condensation, along with salt spray and dry-off. Within one chamber, it is possible to cycle through a series of the most significant corrosion environments. Even extremely complex test cycles can easily be programmed with the controller.

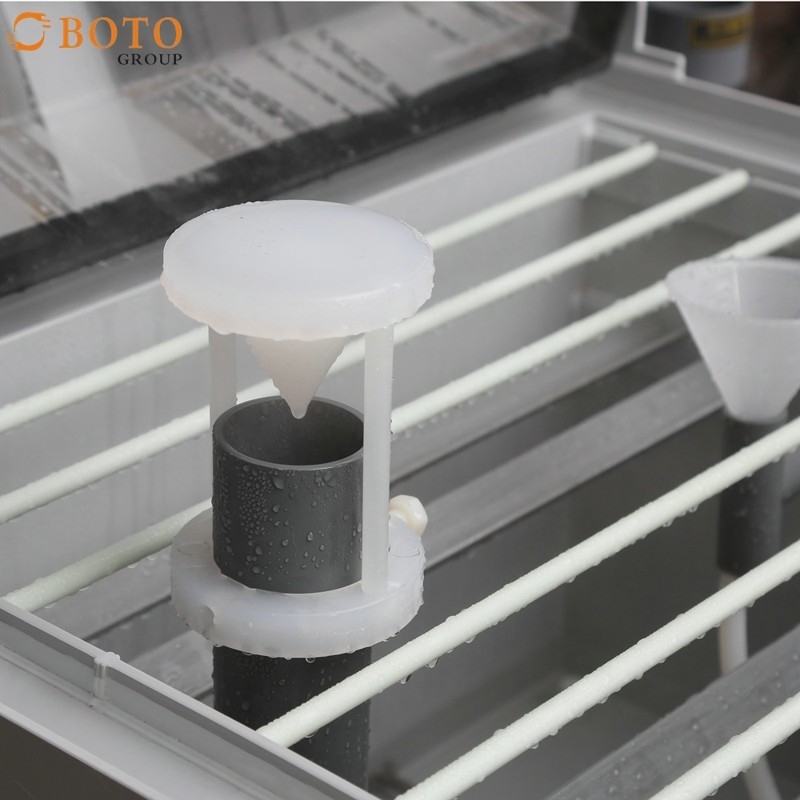

Precise Control of Fog Dispersion The cyclic corrosion chamber has superior fog dispersion compared to conventional systems, which cannot vary volume and distance independently. A variable speed peristaltic pump controls the amount of corrosive solution delivered to the spray atomizer, while the air pressure regulator controls the distance of the “throw.”Note that purified water is required for proper operation of corrosion testers.

Internal Solution Reservoir Space utilization is maximized and maintenance is minimized with the tester's internal solution reservoir. The 120 liter reservoir has enough capacity for running most tests for 7 days or more. The reservoir has an integral salt filter and a built-in alarm to alert the operator when the solution is low.

Fast Cycling Testers can change temperatures exceptionally fast because of their unique internal chamber heater and their high volume cooling/dry-off blower. An additional air heater allows very low humidity dry-off exposures. Conventional chambers with water jackets cannot cycle rapidly because of the thermal mass of the water, nor can they produce low humidity.

Affordable Cyclic corrosion testers offer state of the art corrosion testing technology, reliability, ease of operation and easy maintenance – all at a remarkably affordable price.

Other Accessories

BOTO offers a fog collection kit for the tester, which consists of a set of six graduated cylinders, o-rings, and collection funnels. Also available is a one-year maintenance parts kit, which consists of eight pump tubes, one air filter, two solution filters elements, and a handy hex wrench.

Salt corrosion spray test chamber Configured for your specific tests Grande makes rain and spray testing easier by offering a standard chamber capable of published and OEM proprietary test methods. The standardized design can be configured for the rain/spray tests you need, eliminating the guesswork in buying a chamber. The system is based on the specification requirements, and can also accomplish individual automaker’s tests, as well as electrical-enclosure tests. Our Design BOTO's modular design allows you to add on additional features, depending on the number and type of tests required. One possible choice is to integrate the spray system with a regular temperature and humidity chamber to save money and floor space, while also creating an opportunity to simulate actual operating conditions your product may experience. Our system uses multiple control solenoids to vary the water's spray volume/pressure. A holding tank prepares the water to the desired temperature, if required. A pump ensures the water is delivered in the proper pressure range. The water is fed to a motorized manifold that rotates the spray arms. Each spray arm has an adjustable valve to allow finer control of the spray.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!