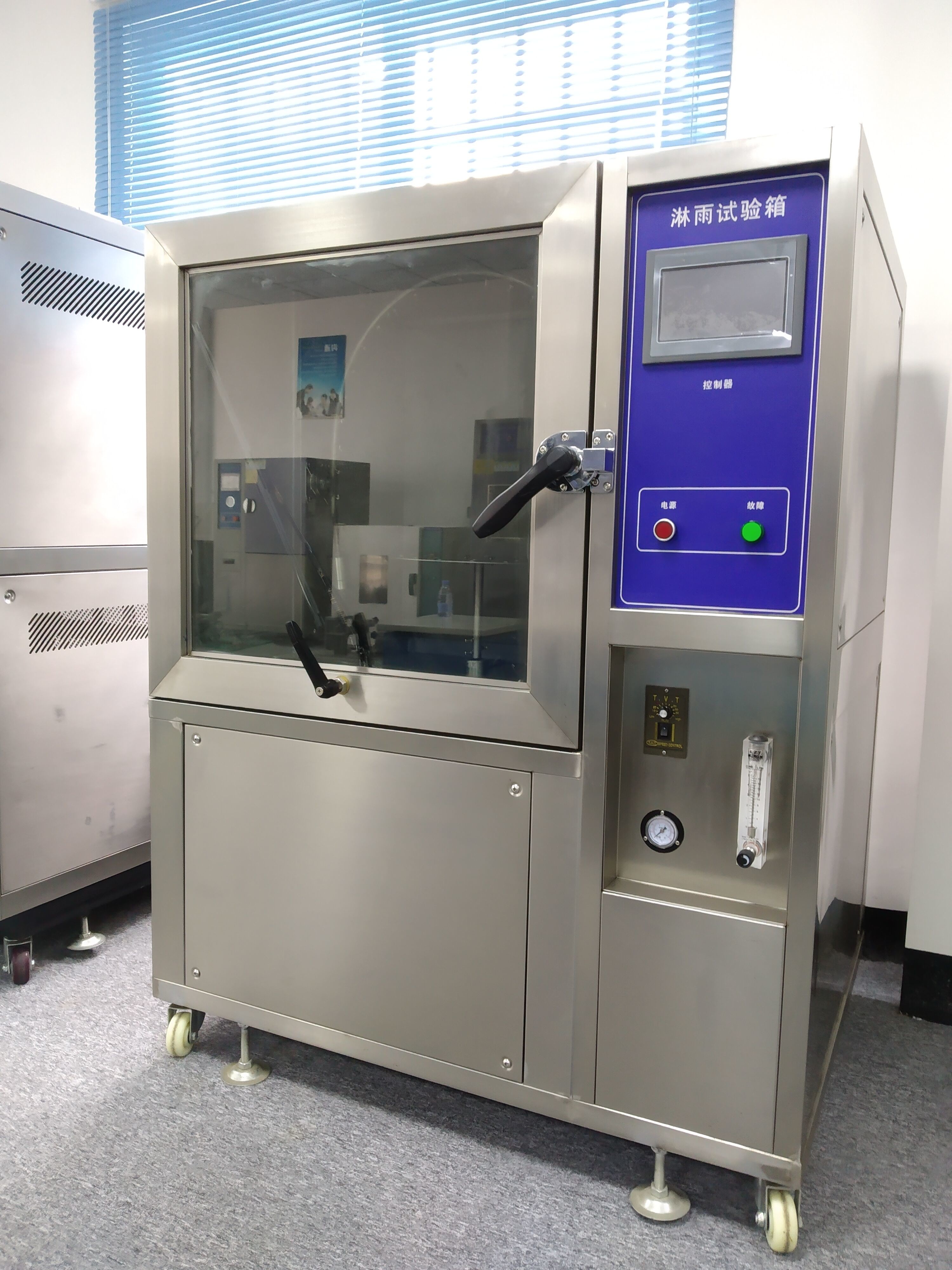

Equipment summary:

This machine used to test anti-rain and waterproof performance for products, the products such as steam locomotive lamps,

wiper performance, waterproof bands, motorcycle instruments, defense industry, navigation systems, missiles, radar cone top,

aerospace industry, IEC IP code specifications that need an additional discussion.

Corresponding standard:

JIS D0203, D5500, SAE J585e, CNS 7138

Applicable industries:

Applied to plastics, rubber, paint, coatings, printing ink, paper, pharmaceuticals, food, cosmetics, textiles, auto parts,

packaging materials, building materials, electricity and the electrical products;

it provide an important testing data for scientific research, product development and quality control

Technical parameter:

| Testing temperature |

Room temperature |

Rt~85°C |

| Inner size |

100(W)*100(D)*100(H) cm or custom |

| Spray volume |

0.07(1±5%)L/min (Every hole in average) |

| Spray nozzle |

Spherical laser drilling,direction: 360°adjustable, make injection of rain fan, to spray the specimen |

| Hydraulic aperture |

φ0.8mm |

| Water spray hole spacing |

50mm |

| Number of blowhole |

16 or 25 |

| Water ring radius |

R400mm |

| Spray nozzle diameter |

φ15mm stainless steel |

| Pendulum Swing tube range |

about±180°(can adjustable to ±45°±60°±90°) |

| Swing speed |

60°/s adjustable |

| Spray pressure |

0~400Kpa adjustable |

| Specimen rotative speed |

4~17rpm (Adjustable) |

| weight |

350kgs |

| Power |

1 phase,220V,5KW |

| Test chamber material |

| Inner size |

1000*1000*1000(D*W*H)mm |

| Dimension |

1300*1500*2200(D*W*H)mm |

| Cabinet material |

SUS304 stainless steel sheet, work room and all the other parts of contact with water are stainless steel or copper. |

| Door |

Large tempered glass door, with manual wiper, Can observe the test condition any time. |

| Seal |

Silicone rubber article |

| Test bench |

φ300mm, mesa of grid. Motor drive the worm gear deceleration, frequency inverter control speed,to the right speed. |

| Test bench turn speed |

2-18r/min (Imported inverter stepless adjustment) |

| Turntable load |

≤100kg |

| Water supply |

imported stainless steel pumps of GRUNDFOS |

| Water tank |

stainless steel water tank, with water filter, water floating ball valve, drain valve, overflow pipe. |

| Water temperature |

Less than +5℃ with room temperature |

| Water source |

Clean the local water by double filtering |

| Lighting system |

turn on--turn off--turn on any time setting |

|

| Electrical control |

|

| Electrical controller |

LCD display controller touch key |

|

| Testing time |

999S adjustable |

|

| Speed control |

variable-frequence governor or stepping motor, speed control smoothly, control accuracy high |

|

| Pressure meter |

Dial gauge display every single test levels of stress |

|

| Flowmeter |

Digital water flow measurement, to display every single test levels of traffic |

|

| Flow pressure control |

Using manual valve control flow and pressure, digital meter indicates flow, stainless steel spring type pressure gauge indicating pressure |

|

| Electrical execute device |

French schneider series electrical components |

|

| Default test time |

0s~99h59m59s adjustable |

|

| Cycle time |

“spray-stop-spray” is a loop,freely setting spray time, stop time, loop times or testing total time. |

|

| Operational environment |

|

| Environment temperature |

RT~50℃(Average temperature≤28℃ within 24H) |

|

| Environment humidity |

≤85%RH |

|

Main functions:

1 the hydraulic flow design type, about 10cm/h commonly, the maximum fall rainfall with the greatest rainfall coming decades 35mm/m. Unique with water device can make rainfall and stabilize the pressure control.

2, RS. Separate control slots, without the operator into change.

3, the machine type B can make the test content from Rt ~ 85 ℃ heat, temperature under test than water temperature high produce a negative pressure, make more accurate test. (MIL - STD).

Accessories Brand

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!