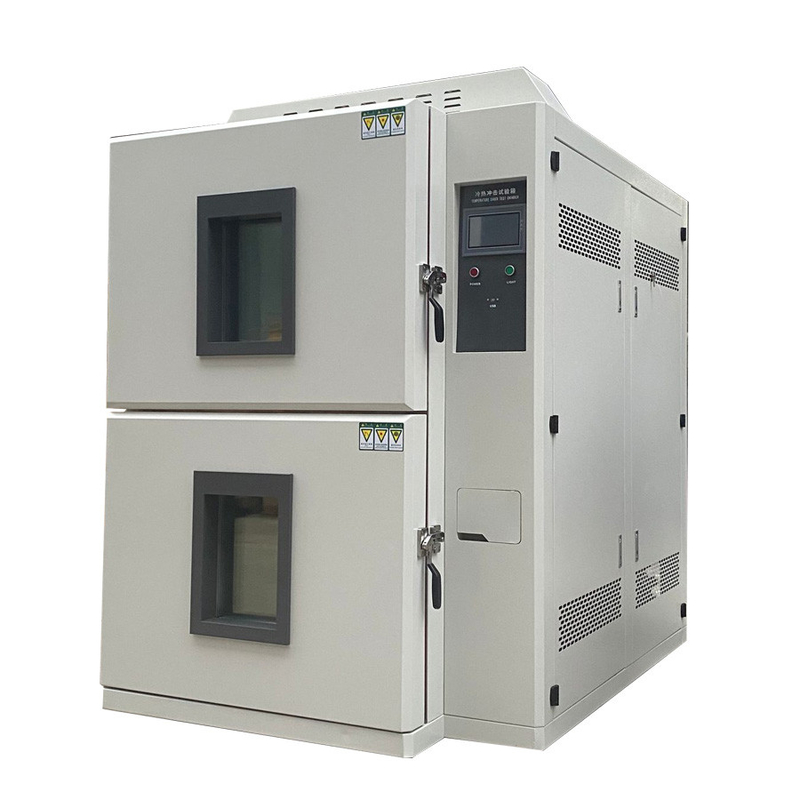

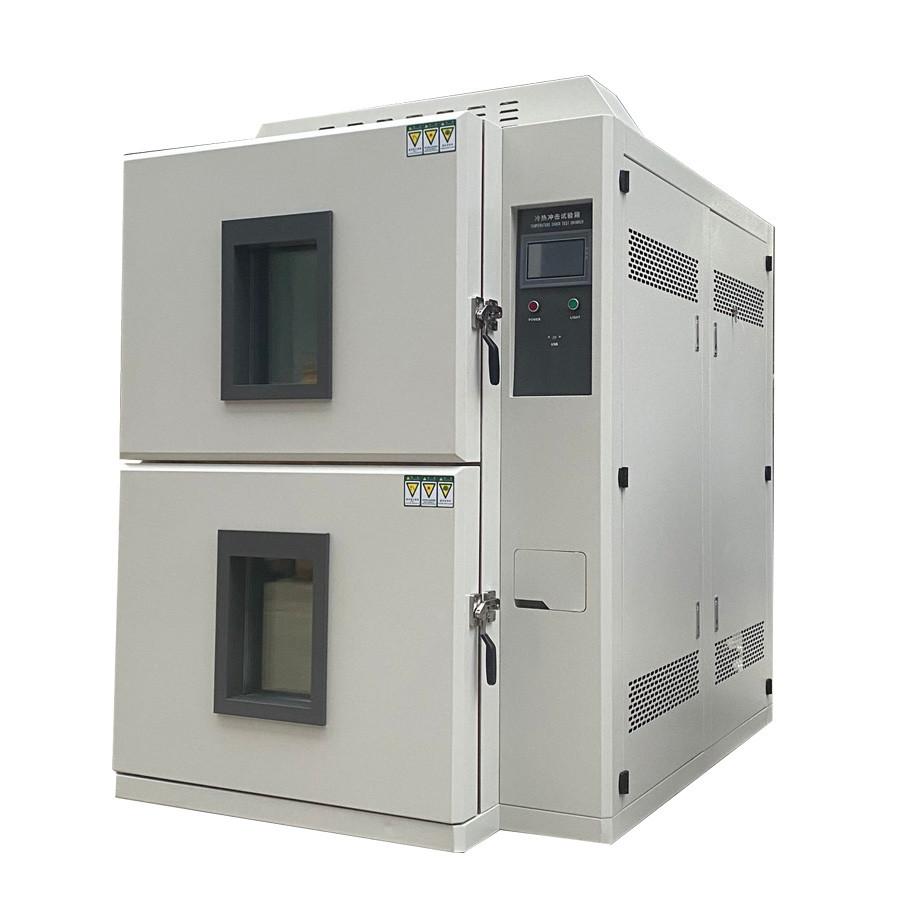

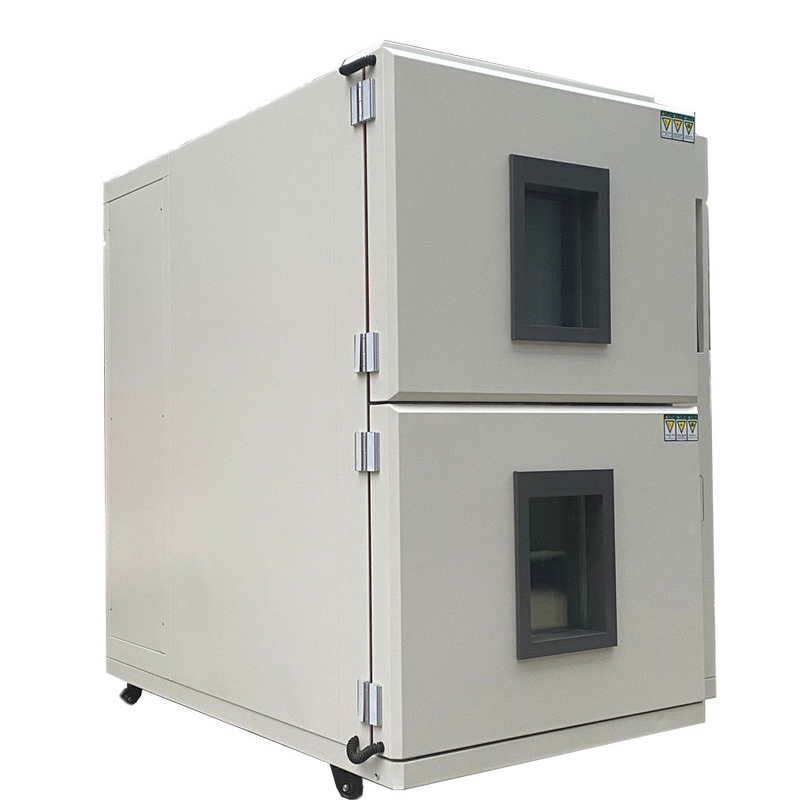

Two box- type hot and cold impact chamber or temperature schock chamber

Two-box temperature impact test chamber(vertical basket/horizontal basket type)

Product Usage:

The temperature impact test box is mainly used for the reliability test of high and low temperature constants and various temperature impacts and temperature changes of electricians, electronic products, components, parts, and metal materials.

Implementation and meeting standards:

GB/T 10592-2008 :high and low temperature test chamber technical conditions

GB/T 2423.22-2008 :temperature change rate test method

GJB 150.3A-2009 :high temperature test method

GJB 150.4A-2009 :low temperature test method

GJB 150.5A-2009 :temperature impact test method

GJB 360B-2009:test methods for electronic and electrical components 107 requirements for temperature shock tests

GB/T 5170.2-2008:test method for environmental test equipment of electric and

electronic products Temperature test equipment

Product features:

New type of refrigeration: -120°C ultra-low temperature cooling capacity to meet the ultra-low temperature shock requirements of users

Efficient and energy-saving: reduce power consumption by more than 30% during low temperature test

Excellent performance: performance indicators better than national and military standard requirements

Compact and flexible: compact, flexible movement, saving space

Simple operation: user-friendly operation interface, one-stop start-up, no professional training

Multiple Protection: Ensure the safety of personnel, test pieces and equipment, worry-free use

Descriptions

Thermal shock test chamber is an indispensable test equipment for the metal, plastics, rubber, electronics and other materials industries. It is used to test the structure of materials or composite materials for endurance under extremely high temperature and extremely low temperature in an instant, to get the chemical change or physical damage caused by thermal expansion and contraction of the test specimen detected in the shortest time.

Features

1.Highly accurate temperature recovery

2.1000 cycles continuous operation (option: defrost-free operation)

3.Accurate and dependable test result (option: product temperature control*)

4.Monitoring product temperature (option: product temperature monitor with trigger function)

5.patent parallel refrigeration system improves reliability

6.Automatic setting of pre-cooling and pre-heating in energy saving, Eco operation mode

7.Minimizing defrosting burden with defrost-free operation (option: defrost-free operation)

8.Parallel refrigerator control system for energy-saving control

Technical indicators

| Product name |

Two box type temperature impact test box |

| Product model |

BT-2TS100 |

BT-2TS180 |

BT-2TS300 |

BT-2TS1000 |

| Nominal volume |

Unit/L |

100 |

180 |

300 |

1000 |

| Inner size |

Width × depth × height (mm) |

500×500×400 |

600×600×500 |

700×700×600 |

1000×1000×1000 |

| External size |

Width × depth × height (mm) |

1020×1200×1850 |

1200×1500×1900 |

1350×1600×1980 |

2450×1800×1980 |

| Basket size |

Width × depth × height (mm) |

350×350×250 |

450×450×350 |

550×550×450 |

800×800×800 |

| Operating mode |

A.vertical basket B. horizontal basket type |

|

Performance

index

|

temperature range |

A,-75℃~200℃ B,-90℃~200℃ C,-120℃~200℃ |

| Impact range |

A,-55℃~160℃ B,-75℃~160℃ C,-85℃~160℃ |

| Temperature fluctuation |

±0.5℃ |

| Temperature uniformity |

≤±2.0℃ |

| Temperature deviation |

≤±2.0℃ |

| heating rate |

RT~+200℃,≤40Min |

| Cooling rate |

A,+25℃~-75℃,≤60Min;B,+25℃~-90℃,≤80Min;C,+25℃~-90℃,≤100Min; |

| Temperature conversion time |

≤15s |

| Temperature recovery time |

≤5Min |

| Exposure conditions |

High temperature exposure 30Mins; Low temperature exposure 30Mins |

| Refrigeration method |

Compressor refrigeration |

| Cooling method |

Air-cooled/water-cooled |

| Main components |

Control System |

Siemens programmable controller + touch screen + independent development program |

| Heating system |

Fully independent system, high efficiency stainless steel finned tube heater |

| Cooling System |

Importer-type scroll compressor |

| Circulatory system |

Temperature and low noise motor, stainless steel centrifugal impeller |

| Main materials |

Carton material |

High-quality carbon steel plate, phosphating electrostatic spray treatment |

| Inner box material |

International standard SUS304# stainless steel mirror treatment |

| Insulation material |

Hard flame retardant polyurethane foam |

| Sealing material |

High and low temperature environment-friendly silicone rubber seal |

| voltage |

380±10% VAC,50Hz;3L+N+G |

| Communication Interface |

RS232 communication interface, USB data interface |

| Standard configuration |

1 sample holder, 1 test lead hole, 1 silicone plug |

| Optional accessories |

Recorder, Remote Control Software, Insulated Sample Holder, Split Manipulator, Dry Air Purge |

| safety devices |

Leakage, short circuit, motor overheating, heater overheating, humidification, water shortage, compressor overpressure, overload, multiple overtemperature protection |

| Environmental requirements |

Ambient temperature: 5 ~ 35 °C, relative humidity: ≤ 85% RH, no strong vibration, electromagnetic radiation, dust and corrosive substances around;

Water supply temperature: ≤ 30 °C, water pressure: 0.1 ~ 0.3MPa, water quality meets industrial water standards;

|

|

Note:

1. temperature performance parameters are in the ambient temperature of 25 °C, studio no load conditions, in accordance with GB/T5170.2-2008 test;

2.according to the specific requirements of users customized non-standard high and low temperature impact test box;

3.This technical information is subject to change without notice.

|

Our Services

If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation muanual. We can provide operation video for machines.

Onsite Service:

1. Device installation;

2. Equipment Operation Test Technology training;

3. Equipment Calibration;

4. Daily maintenance and maintenance of equipment

Free technical training for visiting factories

24-hour Online contact+Free software upgrades+Free information:

1.Product Instruction;2.Product operation instruction/video;3.Experiment Test (test application, test report)

Device Problem Handling:

1. Social media 24 hours online communication;

2. Mail Seamless Docking;

3. Video Conferencing;

4. Artificial free door-to-door service

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!