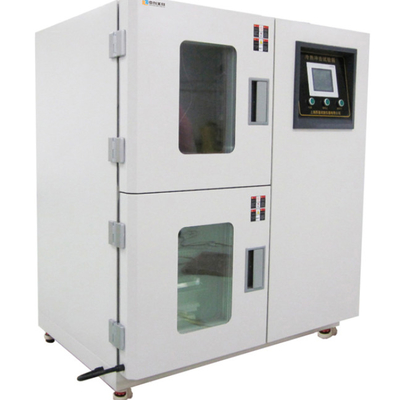

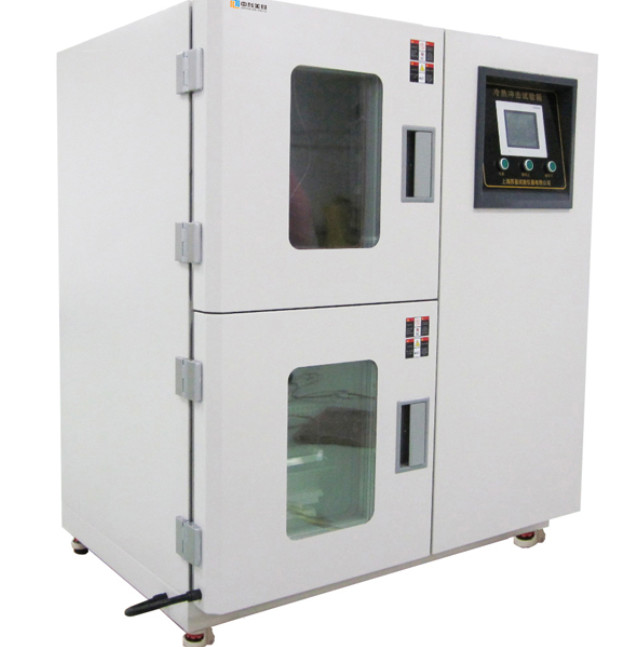

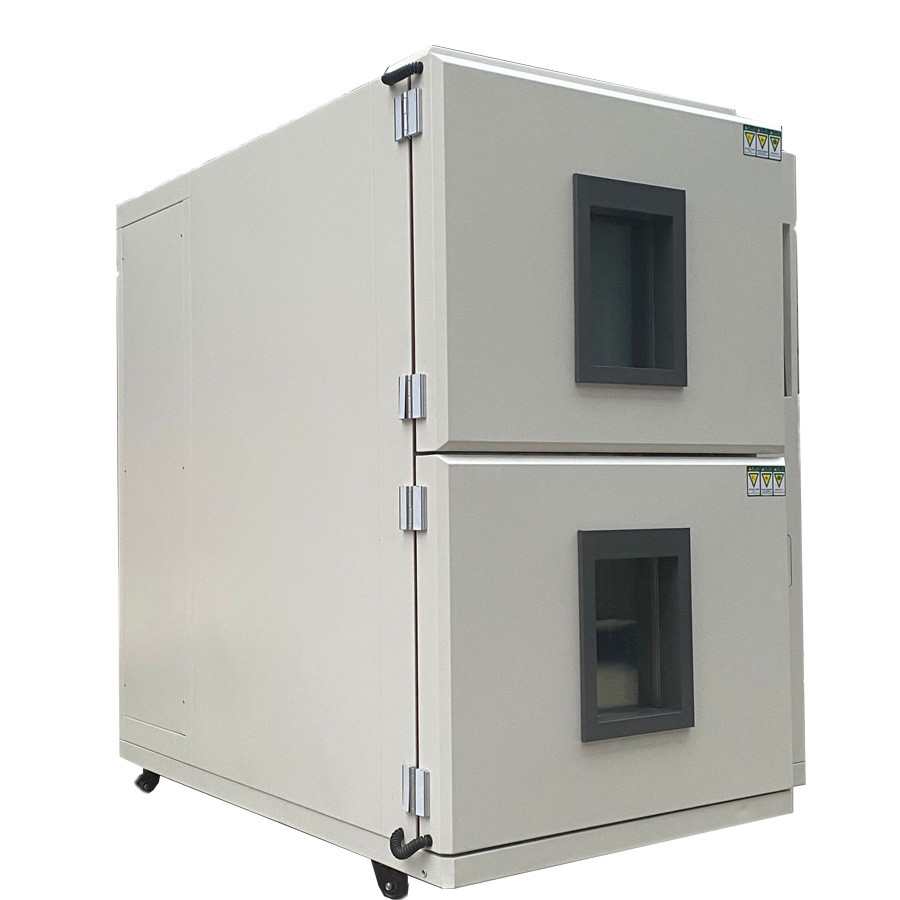

Environmental Control Temperature Humidity Simulation High Altitude Low Pressure Test Chamber

BOTO Climatic Chamber is used to test the material characteristic for wire type, skin type, plastic, rubber, cloth, Equiped with a special ventilation regulator for maintain the fresh air inside when heating. This testing machine design with sophisticated air-displacement adjustment device and a digital voltage meter, current meter, watt-hours, the timer can be used to measure the air replacement rate. Horizontal circulatory air supply system and both sides of airflow regulator to ensure the internal temperature uniformity and stability.

| Model |

BT-280 |

BT-2150 |

BT-2225 |

BT-2408 |

BT-2800 |

|

Inner Size

W×H×D(cm)

|

40×50×40 |

50×60×50 |

50×75×60 |

60×85×80 |

100×100×80 |

| Volume (V) |

80 L |

150L |

225L |

408L |

800L |

|

Temp and Hum

Range

|

A:-20°C~150°C B: -40°C~150°C C: -60°C~150°C D: -70°C~150°C

RH20%-98%

|

|

Function

|

Fluctuation |

±0.5°C ±2.5%RH |

| Deviation |

±0.5°C-±2°C ±3%RH(>75%RH); ±5%RH(≤75%RH) |

|

Controller

Analytical

Accuracy

|

±0.3°C ±2.5%RH |

|

Material

|

Inner Wall |

#SUS 304 Stainless steel |

| Outer Skin |

#SUS 304 Stainless steel |

|

Heat

Preservation

|

High temperature resistant,

high chlorine acid b vinegar foam insulation materials

|

| Refrigeration Way |

Single stage compression refrigeration |

| Refrigerator |

French Tecumseh |

| Refrigerants |

R4O4A USA DuPont environmental protection refrigerant(R23+R404) |

| Condensing Way |

Air-cooled or water-cooled |

| Heater |

Nickel chrome heating wire heater |

| Humidifier |

Semi-closed steam and wet |

| Water Supplying Way |

Automatic cycling water supply |

Main equipment include:

- Constant Temperature and Humidity Test Chamber

- Salt Spray Test Chamber / Corrosion Cyclic Salt Spray Test Chamber

- UV Accelerated Aging Test Chamber

- Mini Environmental chamber / Desktop Environmental Test Chamber

- Walk in Constant Temperature and Humidity Lab

- High Temperature Chamber and Other Lab Test Equipment etc.

Main market:

Company intorudction

BOTO GROUP is a professional manufacturer of various kinds of testing equipment over 20 years. BOTO products are widely used in paper products, packaging, ink printing, adhesive tapes, bags, footwear, leather products, environment, toys, baby products, hardware, electronic products, plastic products, rubber products and other industries, and applicable to all scientific research units, quality inspection institutions and academic fields.

BOTO deals with customers from more than 150 countries and regions. Meanwhile, we are committed to cooperate with different dealers in different countries and regions in order to offer better service. Our mission is to help every customers establish testing labs to ensure the quality of their products.

Our company will continue to develop, innovate and keep faith. We combine with the international testing standards and the specific demands of customers that may establish a new banner in Chinese testing industry.

Production Details

Workshop machine:

Certification

Cooperative partners

BOTO ADVANTAGE

Customers photos

Our Services

During the whole business process, we offer Consultative Selling service.

1) Customer inquiry process:

Discussing testing requirements and technical details, suggested suitable products to customer to confirm. Then quote most suitable price according to customer requirements.

2) Specifications customize process:

Drawing related drawings to confirm with customer for customized requirements. Offer reference photos to show the products appearance. Then, confirm the final solution and confirm final price with customer.

3) Production and delivery process:

We will produce the machines according to confirmed PO requirements. Offering photos to show production process.

After finish production, offer photos to customer to confirm again with the machine. Then do own factory calibration or third party calibration(as customer requirements). Check and test all the details and then arrange packing.

Deliver the products in confirmed shipping time and inform customer.

4) Installation and after sale service:

Defines installing those products in the field and providing after-sales support.

Packing&Shipping

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!